Case Study: All-Encompassing Preparedness and Delivery Solutions for Staatsolie in Suriname

As part of Staatsolie’s planned nearshore exploration drilling campaign for Blocks A, B, and C in Suriname, Staatsolie approached OSRL to work with them on their oil spill preparedness activities. This case study highlights the preparedness services, successful delivery and positive learnings accomplished through the close collaboration between OSRL, Staatsolie, and its contractors.

Background

Staatsolie Maatschappij Suriname N.V. is the established national oil company of Suriname. The Staatsolie corporation consists of multiple business units involving onshore production, refining, fuel delivery and nearshore exploration activities.

The ‘Nearshore’ is a legally defined area north of Suriname’s coastline, which has been assigned to Staatsolie for the distinct purpose of hydrocarbon exploration. The Nearshore currently consists of four contiguous blocks, Block A, B, C and D, that stretch across Suriname’s coastline and cover an area of approximately 11,250 km2. The water depth in the study area ranges from 8m–25m.

In 2015, Staatsolie carried out an exploration drilling project in Block C using its subsidiary, Paradise Oil. OSRL supported this drilling program in the development of an Oil Spill Contingency Plan (OSCP) and delivered Incident Management Team (IMT) training.

After evaluating the results from the previous drilling campaign, in 2018 Staatsolie established the Nearshore Drilling Project Team to drill up to nine appraisal wells during 2019. Due to operational obstacles and the insights during the program, three wells were removed.

OSRL was approached to provide a range of oil spill preparedness services including the development of emergency response oil spill contingency plans, and Tier 1 equipment hire.

Problems, Challenges and Opportunities

Staatsolie engaged OSRL in a range of preparedness activities for their drilling campaign with an overarching objective to ensure they were well prepared in the event of an oil spill incident.

The preparedness activities included the following:

- An emergency response plan

- An oil spill response plan

- Technical support for engagement workshop

- ICS 100, 200 and 402 training

- Incident Management Team (IMT)

- Technical response support (on-site)

- Oil spill equipment hire

Solution

Consultancy

OSRL began the development of Staatsolie’s Emergency Response Plan (ERP) to allow for Staatsolie to plan and prepare for effective emergency response operations to mitigate the potential consequences of an incident to people (local community and personnel), environment, assets and reputation, and enable normal operations to be resumed as quickly and efficiently as possible.

The ERP defined the organisational structure and protocols that would be implemented to respond to any major incident in a safe, rapid, effective, and efficient manner within Staatsolie’s areas of operations.

Alongside the development of the ERP was the project to build Staatsolie’s oil spill contingency and tactical shore plans. OSCPs are key to obtaining and maintaining a drilling licence to operate and are needed to illustrate how a company will respond in the unlikely event of a spill.

Staatsolie recognised that having an OSCP is essential to combating an oil spill effectively. A good plan identifies contingencies through a risk assessment process and shows the strategies needed to avoid or cope with them.

OSRLs approach to developing an OSCP is based on the oil spill contingency planning process, as described by the international good practice guidelines of IPIECA and the international association of oil and gas producers. This process ensures a systematic approach to exploring what can go wrong and assesses oil spill risks and the steps that need to be undertaken in an emergency, thus ensuring the correct arrangements are in place to manage spills.

During the development of the Environmental Sensitivity Impact Assessment (ESIA), Staatsolie held two engagement meetings.

A two-day workshop to validate the Environmental Sensitivity Index (to include the identification of possible groups which can assist in the tactical shore response).

A public consultation meeting which was held to present the results of the ESIA study to key external stakeholders in Suriname. Staatsolie identified the benefit of having OSRL for technical representation at both events because of the close working relationship developed in the preparedness planning process for the exploration drilling operations.

Training

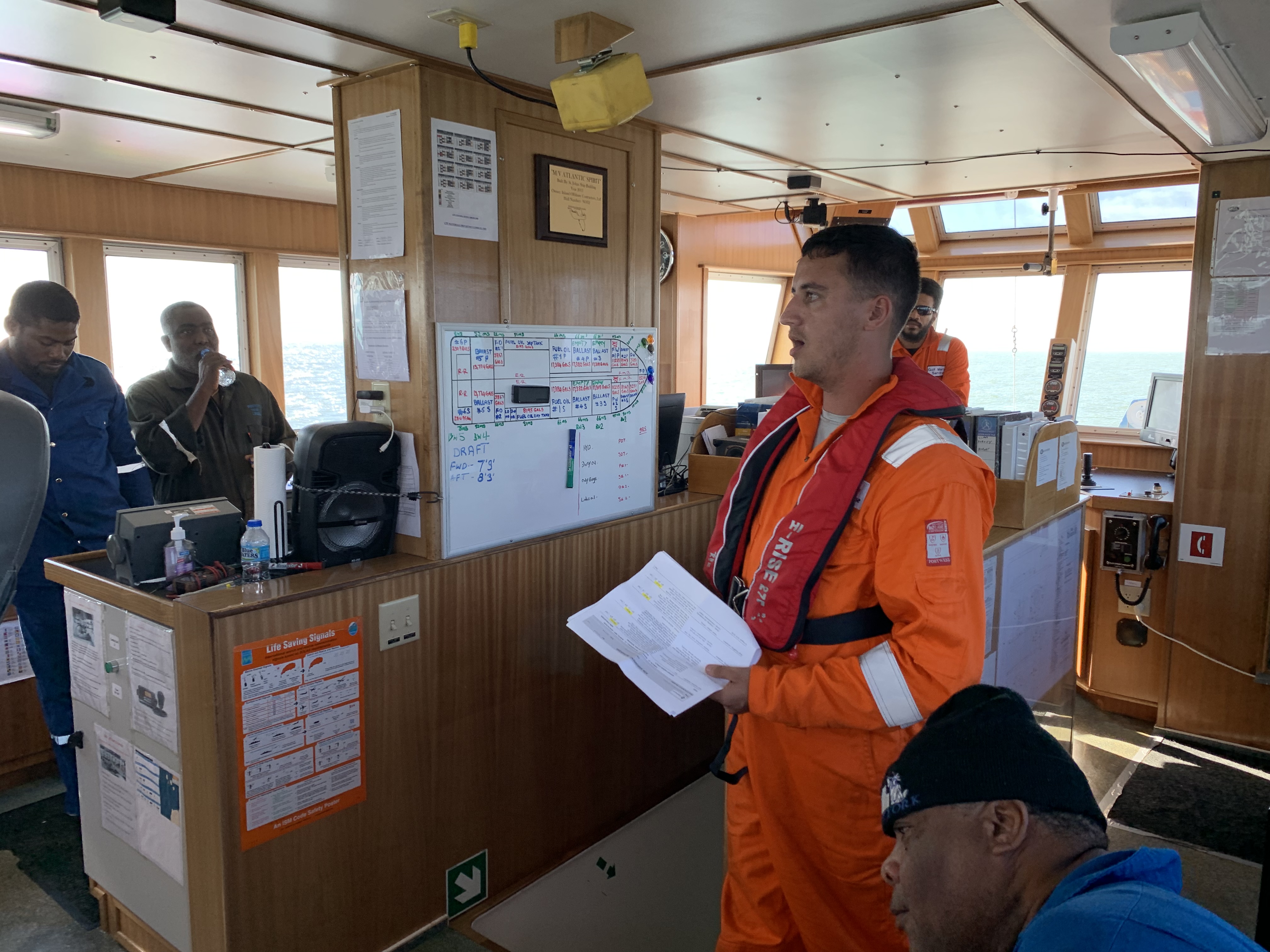

To further develop the proficiency of the Staatsolie Incident Management Team and its support personnel, OSRL delivered ICS 100, 200 and

402 training, providing the Emergency Response and Incident Management Team members with the skills and knowledge to effectively manage spill response operations.

The training was tailored to Staatsolie’s operations. The roles and responsibilities for effectively demonstrating tactical responses were covered in depth in readiness for the demands that occur in a real spill incident. Additionally, Staatsolie requested the delivery of Train-the-Trainer instruction for ICS 300 to allow them to continue onward training in-house.

The programme included good practices from IPIECA Incident Management System for the Oil and Gas Industry, NEBA principles and the All Hazard Incident Management Team principles (FEMA Type III IMT).

Equipment Hire Services

Having response-ready oil spill response equipment on-site for a drilling campaign is essential to effectively reduce the impact of an

oil spill and manage its consequences. The key to any successful response is the understanding of the response strategies and techniques that work in the event of a spill.

A capability review was conducted by OSRL, based on the operational risks in country, and it was agreed that extra Tier 1 oil spill response equipment would be required. As an Associate Member of OSRL, Staatsolie asked OSRL to supply the extra oil spill response equipment.

OSRL’s equipment maintenance service included the provision of trained OSRL specialists to conduct periodic equipment maintenance, which was fulfilled throughout the duration of the project.

Equipment maintenance was conducted to coincide with personnel refresher training.

As part of the agreement to supply oil spill response equipment, OSRL:

- Prepared response-ready containerised OSR equipment:

- 2 x offshore containment and recovery (C&R) systems

- 1 x dispersant package

- 1 x shoreline protection and recovery package

- Delivered equipment to Suriname

- Supervised equipment installation

- Trained operational personnel

- Provided technical advice on preparedness and response techniques and matters

- Maintained the equipment on behalf of Staatsolie

- Supported Staatsolie in returning the equipment to OSRL when operations concluded.

As part of the equipmenrt training activities, OSRL:

-

Trained personnel to safely connect, check and prepare equipment for operational use:

- A full theory session on both containment and recovery system packages and an explanation of use

- Slow time safe boom deployment techniques

- Safe recovery of boom, considering all manual handling issues

- Assembly and use of skimmer system

- Assembly and use of storage tank

- Deployed equipment in a safe and proficient manner

- Demonstrated equipment function, performance and limitations

- Safely demobilise equipment to an organised back to response-ready status.

Standby Technical Response Support

An OSRL technical specialist was seconded to Staatsolie for an eight week period in February and March 2019. During that time, they:

-

Conducted exercises with IMT command, general staff and stakeholders:

-

-

Delivered four exercises a month (February and March 2019 based on Staatsolie’s ERP scenarios).

-

The exercise included evaluation activities resulting in a report on how Staatsolie can improve needs.

-

-

Carried out a remote capability check of the emergency response vessel.

-

Delivered an IMO Level 2 training course.

-

Advised on equipment and response tactics for the Geographical Response Plan.

-

Finalised the ERP, OSCP, waste management and Oil Spill Response logistics plans.

Result

With all the preparedness measures undertaken,the highly tailored on-site support delivering training and exercises provided valuable learnings to all those involved. The newly developed response plans were tested with the exercises, key procedures were validated, and lessons learned were identified and implemented.

Staatsolie recognised that hands-on experience with the response equipment increased familiarity and deployment efficiency.

Staatsolie understood that scheduled training is a key priority, and welcomed regular exercises to test the knowledge gained by its personnel from their vital training with OSRL.

Conclusion

Staatsolie had in place good oil spill preparedness mitigation measures, so they were well-prepared to respond to an incident should one have occurred. Their six well exploration campaign went well with no reported oil spill incidents.

Planning contingencies and considering the possible outcomes prepares drilling organisations, so that they are more likely to successfully meet major goals and targets.

Download the Case Study

Have you got the resources you need to carry out your ongoing activities?

Have the profile of your operational risks assessed including the consideration of regulatory needs, operating environment and resource availability in your operating region, to ascertain equipment hire package requirements which include commissioning, training and maintenance.